Shipping efficiencies achieved through packaging design

02 Apr 2020

Objectives:

• To design a universal packaging solution that allowed painted steel work to be securely shipped from the UK to USA

• To create a common footprint across the range of boxes to help reduce the quantity of SKU’s

• To ensure good levels of container utilisation and ease of loading

Design:

We were asked to design a pack to support the global shipping of metal work between the UK and USA. At the time, no specific packaging had been created; parts were being wrapped in paper and then loaded into wooden boxes for shipping. However, it became apparent that this was inefficient and costly and a solution needed to be found that would not only protect product through global shipping channels, but was sustainable and recyclable too.

It was the intention to create a common footprint across the range of boxes to help reduce the quantity of SKU’s, whilst maintaining a good level of container utilisation and ease of loading.

Furthermore, it had to be easy and labour efficient to pack by production staff.

Outcome:

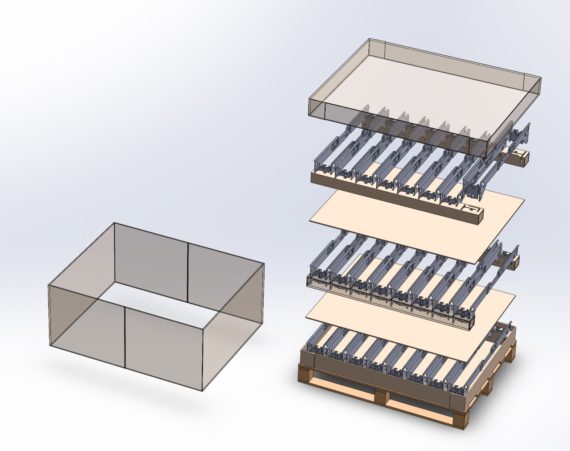

The packaging solution consisted of a pallet style pack which would incorporate a pallet, outer shipper, internal layer trays and top cap.

Each component played a significant part in protecting the product whilst delivering impressive strength.

Several different board grades were used to facilitate the varying requirements including BC Double Wall and CA Double Wall to give different strength requirements and to ensure the internal fittings – designed to keep the metal work in place and separated to protect the paintwork from damage – were robust enough to cope not only with the weight but gave flexibility to ensure all necessary components could be packed using this pack.

Delivery benefits to our customer were evident as the pack is delivered with the outer pack flat packed and the tray, cap and sleeve folded inside reducing the storage required for packaging at our customers production facility.

The pack which is 100% recyclable, including the wooden pallet, also fulfils the requirements to find a more environmentally friendly solution.

Facts and Stats:

One outer pack suited all and inner fitting work with all components

Over 80% pack fill and 80% shipping container fill bringing greater efficiencies

50% more productive lineside packing efficiencies and 25% more efficient unpacking at end user in the USA.

0 comments on “Shipping efficiencies achieved through packaging design”Add yours →